- 4 March, 2022

- Posted by: admin

- Category: News

Depending on the application requirements of the fields or industries, the application of mixed gas is quite common, mixed gas is used for some of the following operational purposes:

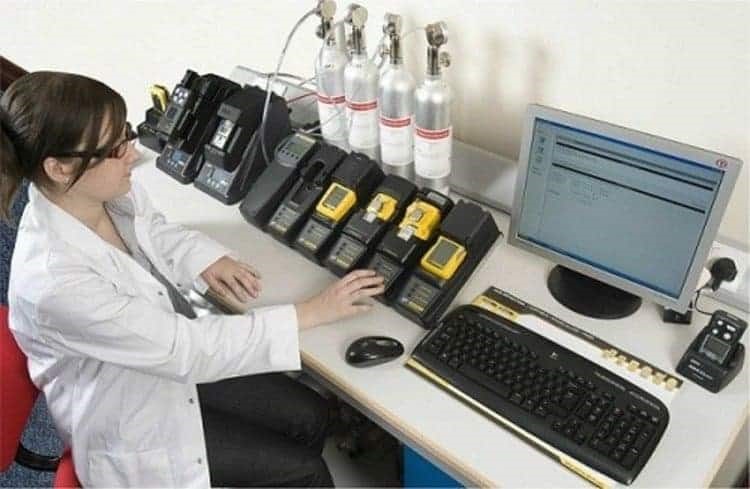

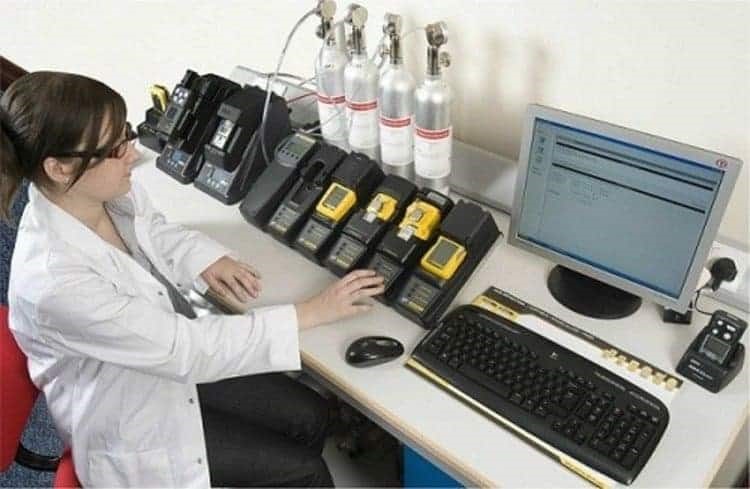

• Calibration of laboratory measuring instruments

• Monitor technology gas flows

• Control the radiation.

• Create standard environment

• Gas chromatography, gas laser, etc.

• Check fire alarms.

• Check the measuring devices in the tracking devices.

• Human activities underwater, water sports, scuba diving.

• Diagnosis and treatment of diseases in medical, anesthesia.

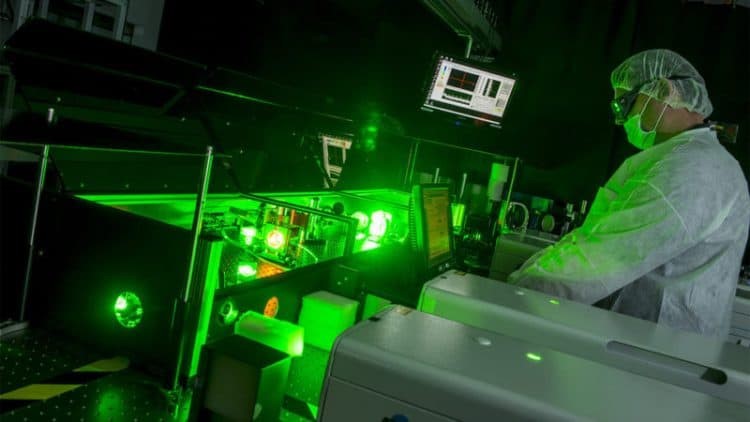

Currently, laser gas is used for:

• Use in devices: CD and DVD players, for printers and scanners.

• Medical uses for surgical purposes and skin treatments

• In the industrial field for cutting and welding materials.

• Use in military and law enforcement equipment for marking on target and measuring range.

• Laser gas applied in scientific research and applied in some other fields.

HELPFUL INFORMATION ABOUT MIXING GAS – CALIBRATION GAS.

What is Mixed Gas?

Mixed gas, also known as mixed gas, is a compressed gas containing more than one gas. And this gas mixture is mixed evenly according to the set parameters.

Gas mixed with components are different compressed air products that are mixed together such as: Co2, Argon gas, O2, N2, N2 gas… These gases are applied and mixed together by volume percentage. and different weights as specified to produce a homogeneous gas mixture.

Depending on the purpose and specific use needs, there will be gas mixtures mixed with different components.

As we all know, with a single gas, it is not always possible to meet all the needs of human use.

This is the main reason that chemists and experienced engineers have researched for the product line of special gas or mixed gas products.

These gases, when put on the market, ensure that the impurities in the mixture are removed, making them stable and most effective.

What is a calibration gas, what is a reference gas?

What is calibration?

Calibration is the activities aimed at determining and establishing the relationship between the measured values of a measurement standard, measuring instrument and the measured value of the quantity to be measured.

Technically speaking, the essence of calibration is the comparison of measuring instruments with reference levels. From there evaluate the error and its other technical and metrological characteristics.

What is a standard gas?

Calibration or mixed gas calibration cylinders are a group of single or mixed gases that meet special requirements. Regarding the factors of mixing tolerance, measurement stability and purity of the feed gas product.

This high-precision calibration mixed gas is used to calibrate measuring instruments.

With a multi-component calgaz calibration gas cylinder will save you more money than with a single calibration gas cylinder.

What is analytical gas?

Analytical gas is a specialized gas in the analysis of experiments. Or it can be said that analytical gas is a special gas used in the field of experimental analysis.

Depending on the purpose and requirements of the experiment, people use different gases or gases or mixtures of gases.

• If it is a single gas, purity is required (For example: purity 5.0: 99.999%; 6.0: 99.9999%…).

• If it is a mixed gas mixture, it is necessary to ensure the correct ratio of the required gas components to be selected.

Impurities mixed in the gas cylinder (such as moisture, dust particles, impurities, etc.) can cause erroneous analysis results.

More seriously, impurities can damage the analytical instruments used. Therefore, the current analytical gas has very high requirements for purity as well as accuracy.